The challenges

With growing demand, retailers are having to deal with increasing competition, as each brand is now offering a range of online services. To stand out and meet the growing demands of customers, it is essential to focus on:

- Quality of services,

- Enhanced lead times

- Product availability

- High flexibility with collection slots

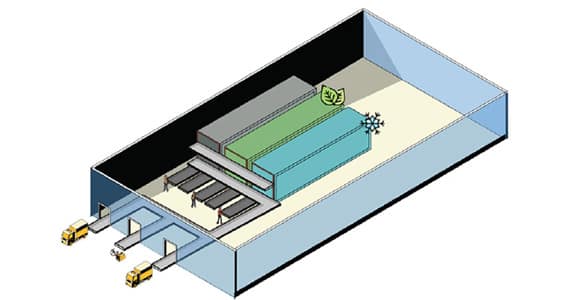

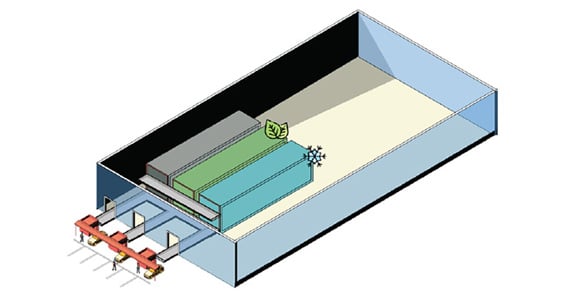

The aim? To provide a faultless customer experience, we need to retain as many versatile and quality-conscious users as possible. These performance levers require appropriate logistics solutions, supported by automation designed for each type of platform.

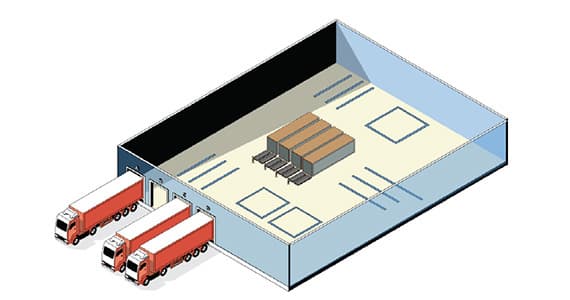

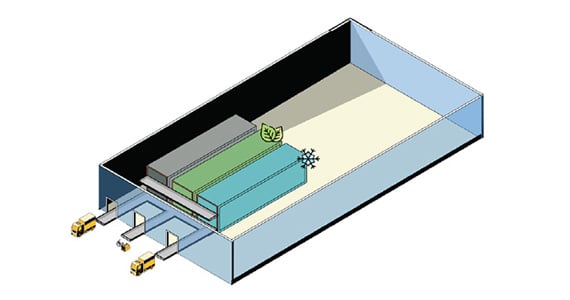

To gain market share, a company must increase its territory and multiply its proximity points. However, this goal must be balanced against the costs of real estate, logistics, transportation and staffing. Industrialized order picking is a key variable in this equation. The industrialization of order picking is an essential major variable in this equation. There are two main models for fulfilling customer orders. The models may coexist within the same business operation, depending on the site:

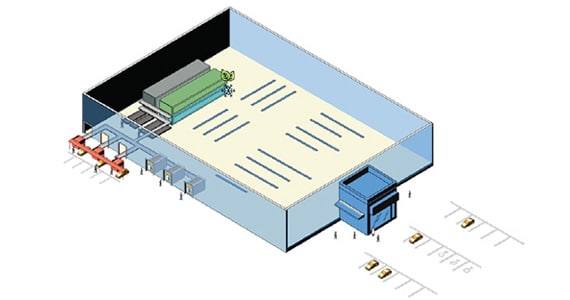

- Order picking in a central warehouse, with the setting up of frequent deliveries to distribution sites.

- Localized order picking, on a dedicated site or attached to an existing point of sale.