Article written by Aurélien LEGUY, Head of Innovation, SAVOYE

Article written by Aurélien LEGUY, Head of Innovation, SAVOYE

Robotic lockers at the heart of comprehensive view of logistics

For almost 20 years, the rise of e-commerce in the grocery shopping sector has been accompanied by a proliferation of delivery methods and options available to consumers. These new arrangements are now raising fundamental questions about their relevance, in terms of their adoption by consumers and the prospects of them being profitable for retailers, as well as their societal, economic and environmental effects.

Of all the collection models, robotic lockers appear to stand out, to the point of generating a real whirlwind of different concepts in recent years.

Many supermarket chains are trialing them on a local level, in order to better understand their use by customers and their economic profitability, but are not moving to trials involving large-scale deployment. Although the idea of the relevance of robotic lockers is advancing, we are still not seeing a real consensus being formed as regards the optimal mode of operation nor an inflection point for the adoption of this collection method by supermarket chains. In order to identify a viable business model, it is essential to think beyond the locker itself and to consider the overall logistics plan on a local level.

An overall view of logistics

Robotic lockers, drive-through points, home delivery and click & collect, provide a complete and complementary range of collection and delivery options, offered alongside traditional grocery shopping in hypermarkets and supermarkets. The idea is not to rely on one channel rather than another, but to offer a range of services capable of satisfying the maximum number of customers’ everyday needs.

The relevance of the robotic locker lies in its ability to offer a solution, which exceeds the geographic and time-related constraints of other collection methods. Drive-through points, home deliveries and click & collect pick-ups, involve traveling to or from a shopping area, as well as a pre-booked time slot for collection. Offering greater flexibility, customers can collect from a locker at any time and, potentially, on foot.

Alongside the emergence of these new consumption patterns, the hypermarket and supermarket model is losing ground and needs to reinvent itself. New physical and digital flows require a transformation of these retail outlets into spaces that are able to work with all collection and delivery channels. We are seeing these stores develop into genuine micro-fulfillment centers where the addition of new options enables market share to be gained and retained. Therefore, the aim is to make this multi-channel supermarket model profitable.

What are the levers for ensuring the viability of the economic model?

In the “traditional” grocery shopping model, order picking and home delivery are at the customer’s expense. With drive-through points, home delivery and robotic lockers, it is the chain that covers all picking operations and bears some or all of the delivery costs. To increase their business while remaining competitive, retail chains need to control this increase in operating costs. They have two levers at their disposal:

- The first is the centralization and automation of order picking operations for collections from lockers, drive-through points and home delivery. On the one hand, for reasons of compactness – land is scarce and expensive – and, on the other hand, for operational productivity reasons. Investment in a robotic picking and storage system is essential for achieving a high level of operational performance in a small space and, therefore, making the business profitable.

- The second lever is the establishment of an information system, which is able to orchestrate all processes, from product storage to supplying different collection and delivery options. Software intelligence is key to improving the efficiency of each method: responsiveness when the customer arrives at a drive-through point, the shortest route for a home delivery round, etc.

The management of robotic lockers must provide responses to two key points. We are specifically working on predictive management of the occupancy time for lockers, with the aim of estimating the number of free lockers and improving the system’s profitability. Learning by statistical observation is a first step, and it is possible to go further by estimating a collection time, by means of machine learning, depending on the content of orders. We are also considering the automated verification of returns made by customers using lockers. This will include a product checking process, which may involve scanning the item barcode, weighing or even automatic recognition of items by means of a vision system.

A beneficial impact in terms of reducing CO2 emissions

Beyond the economic model, there is also the question of the environmental impact of collection options, and it must be said that there are powerful arguments in favor of robotic lockers in this respect.

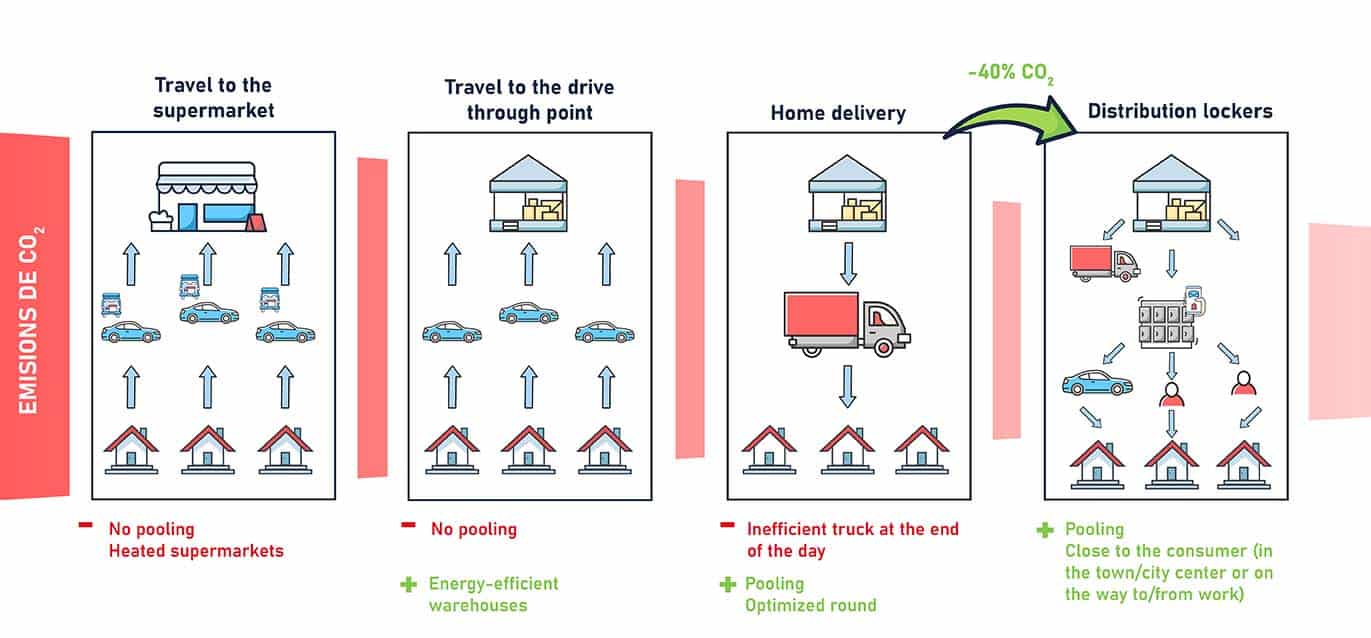

Let’s take the most common scenario, where the customer shops for groceries on a weekly basis and would like a wide selection of products. Home delivery is traditionally the option with the lowest carbon footprint, as the result of pooling orders by means of an optimized delivery round, whereas drive-through points and “traditional” grocery shopping result in a large number of journeys between supermarkets and homes.

Supplying a network of robotic lockers proves to be an even more attractive option than delivering to customers one by one. This is the effect of the centralization of delivery points offered by this new method. With judiciously positioned lockers to generate collections on foot or on the way to/from work, the CO2 reduction is up to 40% compared to home delivery.

As a result, the contribution of robotic lockers to reducing CO2 differs depending on the population density. In urban areas, lockers will be installed in a dedicated area, or more probably in an area combining a convenience store with lockers: groceries are collected on foot or on the way to/from work using a soft mode of transport. In peri-urban areas, lockers must be positioned on the routes between homes and workplaces, to minimize detours to collect shopping. The only exception to this is the use of lockers in rural areas, which does not provide any substantial gains in terms of the carbon footprint, but represents a service that enhances the attractiveness of certain areas.

Conclusion

As we have outlined, robotic lockers offer a major and serious opportunity as part of the range of collection and delivery options, which have emerged in recent years. Although there are strong arguments in favor of them, there are many questions surrounding robotic lockers, which are currently curbing the democratization of their use and large-scale deployment. Current trials are prompting a rethink of so-called last mile logistics models, beyond just lockers, relating to their supply and order picking methods. What also remains to be clarified are the ideal locations for collection points and MFCs, as well as the order profiles and responsiveness targets, and the flows expected by customers for each location.

Once these issues have been resolved, the chances that these systems will become established are high, in view of the huge gains in terms of customer service and the environment as part of a comprehensive view of logistics.