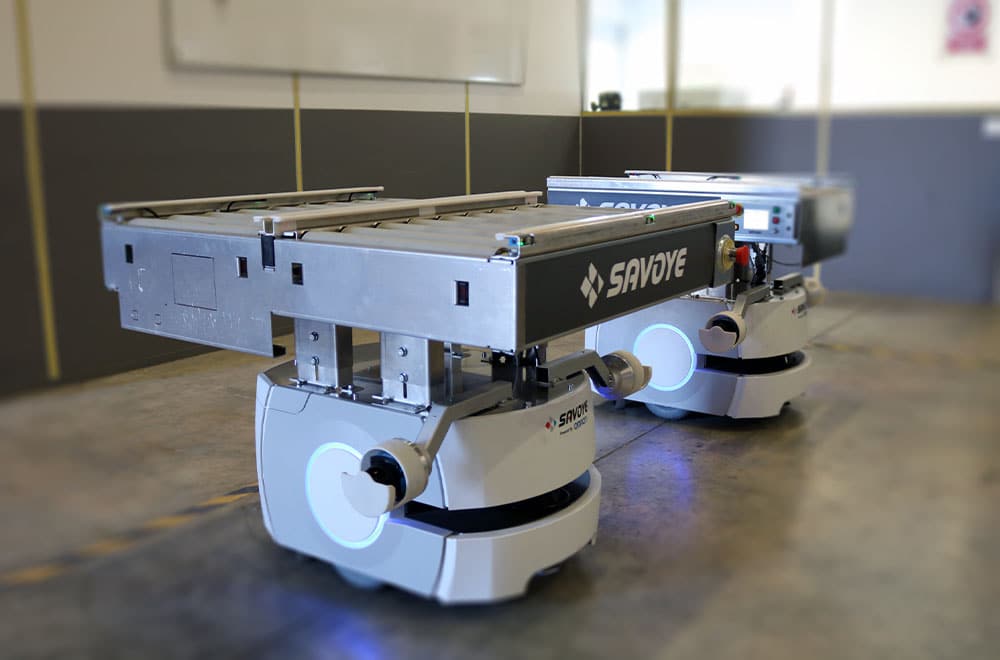

A flexible and economic alternative to manual processes

FLEEXEE mobile robots move fully independently, transporting packages and items throughout the warehouse, sparing operators from:

- Trips between different zones (launching, picking and packaging)

- Fatigue from handling carts

Therefore, operators remain in their zone, and can spend as much of their time as possible on high-value operations. The FLEEXEE Mobile Robot solution can be used in stand-alone mode, natively interfaced with SAVOYE WMS and WCS software, or in addition to an automated system.